About Us

Welcome to NPHP

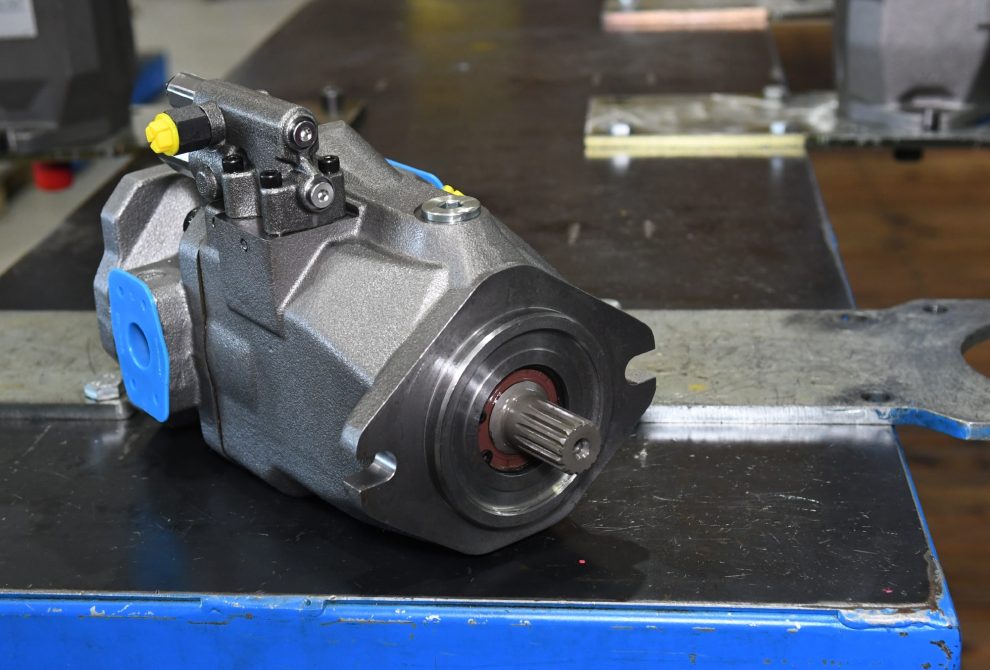

Our workshop has various machining machines such as a lathe, a drilling machine, a semi-cnc milling machine and a honing machine. We work with periodically NEN3140 approved machines and tools for repairing, maintaining, modifying and manufacturing hydraulic systems and components.

One of the first rotary hydraulic motors to be developed was that constructed by William Armstrong for his Swing Bridge over the River Tyne. Two motors were provided, for reliability. Each one was a three-cylinder single-acting oscillating engine. Armstrong developed a wide range of hydraulic motors, linear and rotary, that were used for a wide range of industrial and civil engineering tasks, particularly for docks and moving bridges. The first simple fixed-stroke hydraulic motors had the disadvantage that they used the same volume of water whatever the load and so were wasteful at part-power. Unlike steam engines, as water is incompressible, they could not be throttled or their valve cut-off controlled. To overcome this, motors with variable stroke were developed. Adjusting the stroke, rather than controlling admission valves, now controlled the engine power and water consumption. One of the first of these was Arthur Rigg's patent engine of 1886. This used a double eccentric mechanism, as used on variable stroke power presses, to control the stroke length of a three cylinder radial engine. Later, the swashplate engine with an adjustable swashplate angle would become a popular way to make variable stroke hydraulic motors.